12 December, 2024

12 December, 2024Meltio’s hybrid additive manufacturing technology has achieved another milestone, successfully repairing a critical part aboard the USS Somerset during RIMPAC 2024 naval exercises. This accomplishment highlights the transformative potential of the technology developed by the Spanish multinational at its headquarters in Linares (Jaén), solidifying its role as a key tool for logistics and operability in demanding environments.

Engineering challenges resolved at sea

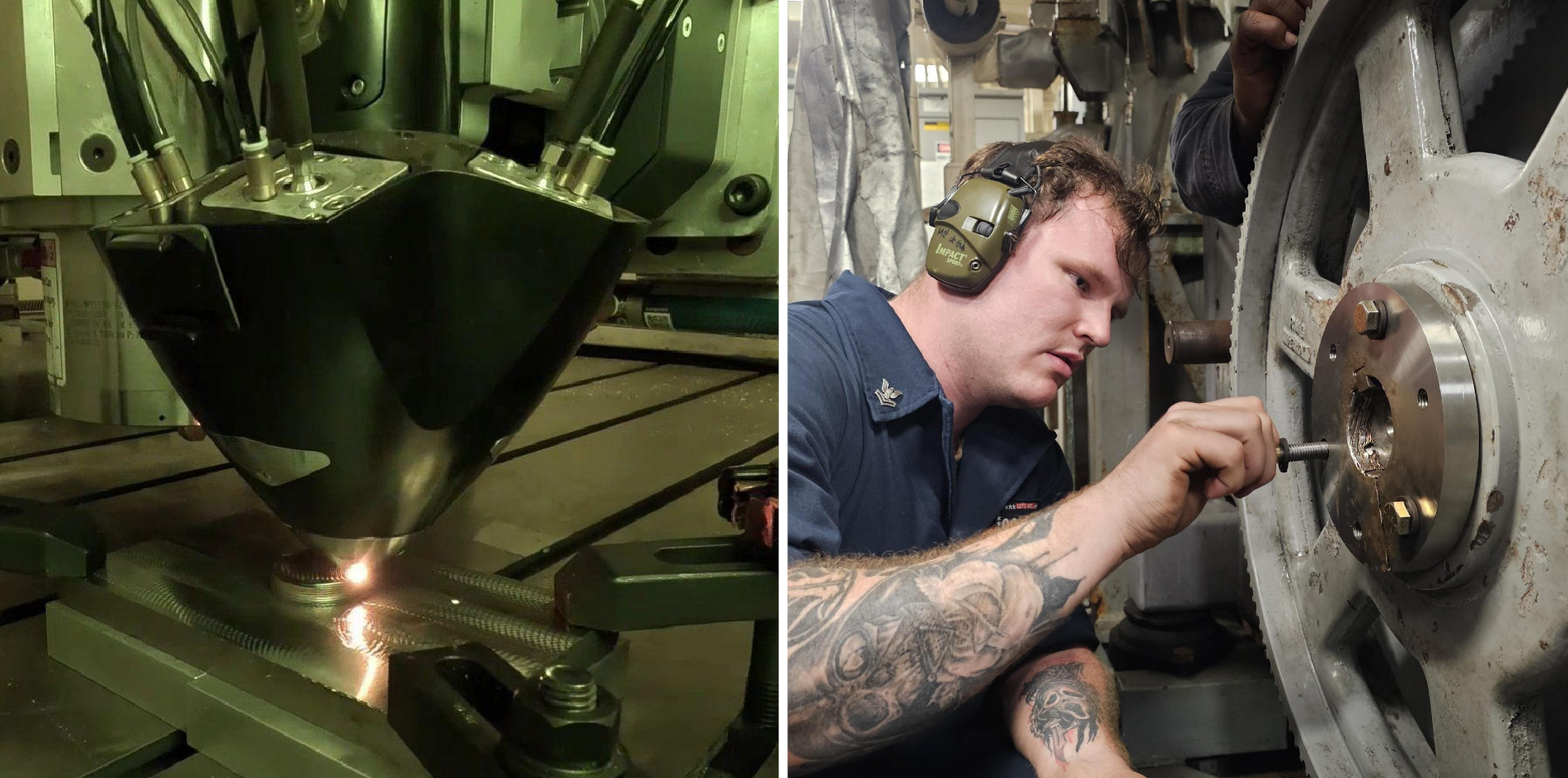

During RIMPAC 2024, the largest multinational maritime exercise globally, the USS Somerset crew faced the failure of a reverse osmosis pump crucial for potable water production. Without this part, the ship’s mission could have been jeopardized. However, with the SAMM Tech system—integrating Meltio's wire-laser Directed Energy Deposition (DED) 3D printing head and a FANUC-controlled CNC system—the part was fabricated aboard in mere hours.

Meltio's system enabled the creation of a new component using materials like stainless steel and titanium, bypassing a traditional supply chain wait of weeks or months. According to Charles Wallace, a mechanical engineer from the Naval Postgraduate School, this solution was instrumental in maintaining the ship’s operability.

Setting a standard for naval defense

Previously validated aboard the USS Bataan in 2022, Meltio's technology is now used across other ships and defense organizations globally. Its all-in-one capability allows crews to fabricate, mill, and finalize critical parts onsite, eliminating dependency on external suppliers and ensuring minimal response times.

Additionally, the technology does not require post-processing or heat treatments, making it particularly suitable for military applications demanding rapid, reliable solutions.

Key advantages for the naval sector

The integration of Meltio’s hybrid 3D printing offers numerous benefits to the naval sector, including:

A paradigm shift in military logistics

Meltio’s technology is redefining military logistics, enabling more sustainable and resilient operations. This advancement not only optimizes onboard resources but also strengthens responsiveness in remote or emergency scenarios.

The success aboard USS Somerset reaffirms the value of this technology in mission-critical scenarios, marking a fundamental shift in how naval forces approach manufacturing and maintenance challenges at sea.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.