04 November, 2022

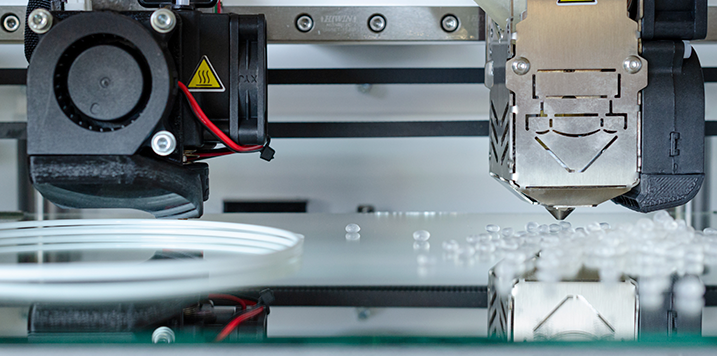

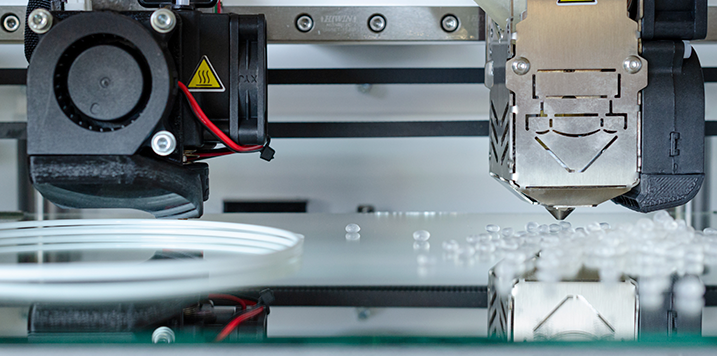

04 November, 2022The world of 3D printing is constantly growing, every day someone is working to innovate and facilitate the use of this technology. Indart3D are no exception, TUMAKER manufacturers are incorporating different benefits in their printers. We are talking about a new machine that will be presented at the international trade fair Formnext, with exchangeable heads, prints with double independent heads and much more that will make the evolution and development of multiple technological projects easier.

It offers the ability to work with both formats of additive manufacturing, filament and pellets. The duality and independence of the machines also gives us the possibility of greater efficiency. The innovation is found in the incorporation of a new option that will help the handling and comfort of the machine. The heads can be easily removed and replaced, depending on the user's needs. This will allow different combinations of printheads to be used on the same printer. All this without losing the machine's printing dimensions.

As for the filament, the new Hemera Direct Drive heads are incorporated, with them the best and most developed FFF technology is maintained in their machines. In addition, the added value that they have thanks to the ease and speed with which the nozzle can be changed allows for varying print speeds and qualities.

Last but not least, with the PELLET head, a variety and versatility of materials is achieved, as well as significant economic savings. This head allows the reuse of materials, whether 3D printing materials such as plastics or other materials such as metals, organic materials, etc., converting them into pellets and printing new parts, thus entering into a CIRCULAR ECONOMY and achieving a reduction of the carbon footprint in each process.

04 November, 2022The world of 3D printing is constantly growing, every day someone is working to innovate and facilitate the use of this technology. Indart3D are no exception, TUMAKER manufacturers are incorporating different benefits in their printers. We are talking about a new machine that will be presented at the international trade fair Formnext, with exchangeable heads, prints with double independent heads and much more that will make the evolution and development of multiple technological projects easier.

04 November, 2022The world of 3D printing is constantly growing, every day someone is working to innovate and facilitate the use of this technology. Indart3D are no exception, TUMAKER manufacturers are incorporating different benefits in their printers. We are talking about a new machine that will be presented at the international trade fair Formnext, with exchangeable heads, prints with double independent heads and much more that will make the evolution and development of multiple technological projects easier.