17 December, 2024

17 December, 2024Renishaw, a global leader in additive manufacturing, precision measurement systems, and intelligent manufacturing solutions, continues to solidify its position in the aerospace industry with the adoption of its RenAM500S Flex additive manufacturing machine by engineering company CiTD.

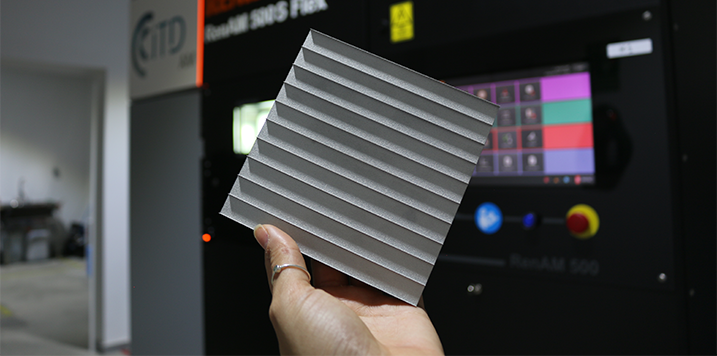

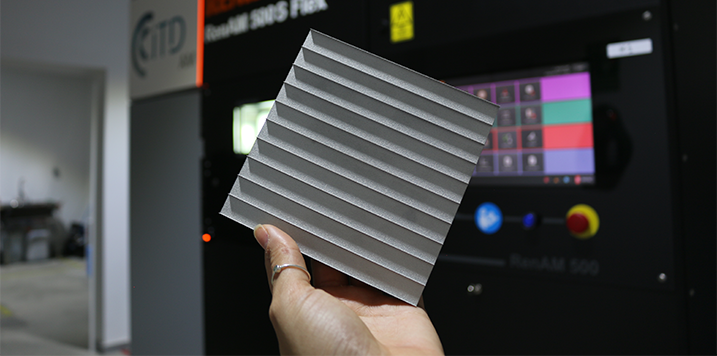

Part of the RenAM 500 series, the RenAM500S Flex stands out for its flexibility and precision, two essential features for sectors with stringent requirements like aerospace. Equipped with a robust powder bed system and the ability to optimize parameters for different materials, this advanced solution enables the production of complex, high-performance components.

Cutting-edge technology for demanding applicationsThe RenAM500S Flex features a single high-power laser and precise digital control, ensuring reliable performance while offering flexible powder extraction. This flexibility simplifies material changes without compromising productivity, a critical advantage in fast-paced manufacturing environments.

According to Marta García-Cosío, Director at CiTD, the machine was selected for its technological maturity and open-material platform: “

Among the various powder bed systems on the market, we chose the RenAM500S Flex for its flexibility in creating optimized parameters for different materials and the freedom to use materials from various suppliers, along with the excellent technical and human team at Renishaw Ibérica.”

Renishaw driving additive manufacturing innovationAdditive manufacturing is transforming production processes by enabling the creation of complex and optimized geometries that traditional methods cannot achieve. This technology also plays a critical role in reducing component weight, a key factor in aerospace to improve fuel efficiency and overall aircraft performance.

Renishaw’s RenAM500S Flex delivers not only outstanding dimensional accuracy but also a flexible platform tailored to meet specific customer needs. Its advanced capabilities enhance productivity, efficiency, and competitiveness, positioning Renishaw as a strategic partner in critical industries.

Commitment to industrial innovationThe implementation of the RenAM500S Flex at CiTD highlights Renishaw’s commitment to technological innovation and the evolution of additive manufacturing for industries where precision, performance, and process optimization are paramount.

Renishaw’s combination of robust technology and adaptability reinforces its role as a key provider of advanced manufacturing solutions. By enabling the development of components that meet the highest quality and performance standards, Renishaw continues to lead the global transformation of industrial production processes.

17 December, 2024Renishaw, a global leader in additive manufacturing, precision measurement systems, and intelligent manufacturing solutions, continues to solidify its position in the aerospace industry with the adoption of its RenAM500S Flex additive manufacturing machine by engineering company CiTD.

17 December, 2024Renishaw, a global leader in additive manufacturing, precision measurement systems, and intelligent manufacturing solutions, continues to solidify its position in the aerospace industry with the adoption of its RenAM500S Flex additive manufacturing machine by engineering company CiTD.