28 March, 2023

28 March, 2023Versatility of Additive manufacturing allows to reach custom made products at a manageable cost. Having said that, hand by hand with the traumatology team of Basurto’s Hospital, led by the Dr. Iñigo Cearra, Optimus 3D developed a sanitary splint that is custom made manufactured whose function is to treat a pathology of the hand: Rhizarthrosis. For this disease, the unique treatment currently available for rhizarthrosis is immobilization of the affected part, the thumb joint. This joint is an awkward case since the immobilization of the thumb can mean a handicap for the daily tasks of the patient by interfering with the clamp action of the hand.

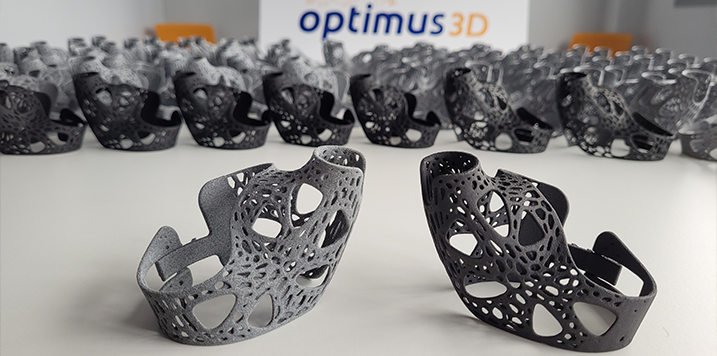

Thanks to additive manufacturing, Optimus 3D has developed an immobilizing splint that meets the needs of the treatment without interfering with the user’s daily tasks. It is flexible to contact with the skin and firm and rigid in the affected joint. Additionally, it is specifically designed not to hinder the natural perspiration of the skin and it is suitable for swimming outdoors in the pool or the beach.

The splint is tailored to the patient, thanks to a proprietary 3D scanning application developed for IOS that allows to take the medical image with an I-Phone or an I-Pad together with Optimus3D’s positioning device.

After carrying out a detailed clinical study that yielded very good results in the treated patients, this technology is already available to patients with this pathology and professional doctors who want to offer a customized and functional product to their patients with rhizarthrosis.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.