24 October, 2024

24 October, 2024The LORTEK technology centre, a member of the Basque R&D Alliance (BRTA), reinforces its position as a benchmark in the field of metal additive manufacturing with its participation in the FORMNEXT 2024 fair. On this occasion, LORTEK will be exhibiting its latest technological innovations, aimed at supporting the digital and energy transition of industry, with solutions ranging from the development to the manufacture and repair of high added value components.

Innovation in technological infrastructures and experience in additive manufacturing

LORTEK stands out for its comprehensive approach to additive manufacturing, covering all stages of the value chain. Its research work includes both the development of advanced hardware and software and the implementation of digitisation technologies, ensuring that the solutions offered are sustainable, robust and adapted to industrial needs. At FORMNEXT 2024, the centre will present a range of advanced infrastructures and capabilities for large-format component manufacturing.

CIRCLE: Large-format additive manufacturing and repair

One of the most prominent developments to be presented is CIRCLE, a multi-robot cell designed for the manufacture and repair of large components, such as shafts up to 3 metres long or moulds up to 2.5 square metres. This hybrid Directed Energy Deposition (DED) technology combines 3D scanning with both laser and arc deposition processes, enabling unprecedented flexibility in multi-material additive manufacturing.

The implementation of CIRCLE aims to transform industrial production by offering faster and more efficient solutions in the manufacture of large parts, making it a key tool for companies looking to increase their competitiveness and productive capacity.

Advances in additive manufacturing technologies

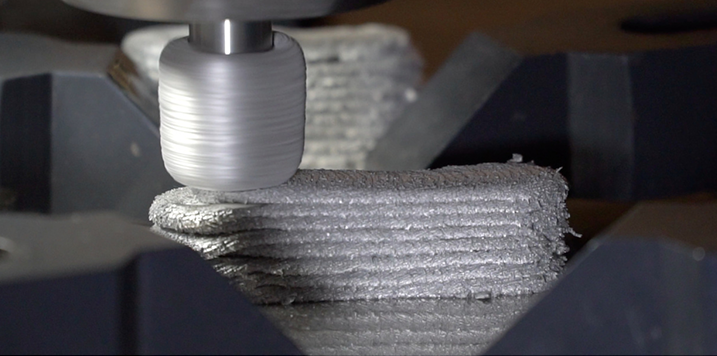

Among the technologies that LORTEK will be showcasing are advances in FSAM (Friction Based Additive Manufacturing), a solid-state process designed for the manufacture and repair of complex parts. This method is especially useful for materials that present difficulties in conventional welding processes, expanding the possibilities for industries that need high precision and durability components.

In addition, developments in other key areas will be presented:

LORTEK, with its expertise in metal additive manufacturing and commitment to innovation, presents itself as a strategic partner for companies looking to adapt to the challenges of the digital and energy transition. Its solutions enable industries to optimise their production processes and develop high-performance components, positioning LORTEK as a key player in advanced manufacturing.

Interested visitors can learn more about these innovations at stand A44, located in Hall 11.1 at FORMNEXT 2024.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.