07 November, 2018

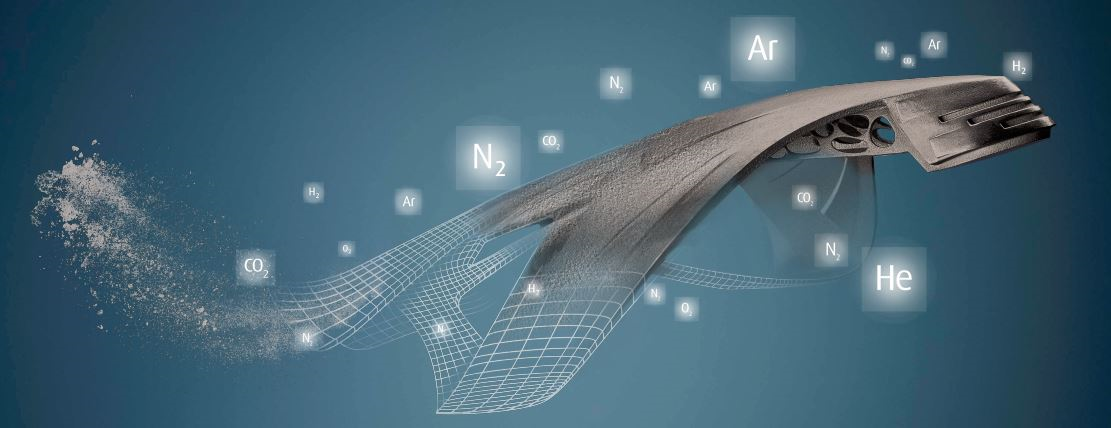

07 November, 2018Discover our ADDvance® range of gases and technologies for the Additive Manufacturing industry. Where we will reveal gas-enabled excellence from powder to precision parts. Find us in Hall 3 Booth D90 from the 13 – 16 November, Frankfurt Germany.

Precision is key when it comes to additive manufacture parts, that is why Linde are committed to supplying you with innovative and highly reliable gas-enabled technologies that will help improve your productivity and most importantly precision.

This year in FORMNEXT we will show our Additive Manufacturing specific product range: ADDvance®:

ADDvance® Powder Cabinet, is an innovative system that allows to store the powder avoiding the exposure to atmosphere, thus to the moisture. The cabinet has humidity sensors, inertisation system and a functional display allowing the parametrization to obtain the required conditions.

ADDvance® O2 Precision is a key equipment to obtain reproducibility in the 3D printing process. It is possible to obtain reproducible and good quality results through the analysis and monitorization of process chamber atmosphere, mainly in titanium alloys where precise control of oxygen levels makes the difference.

Also, we will show how our products can support you through every step of the AM process chain from powder production to handling and storage, to optimising the print chambers atmosphere, to finally effective and efficient surface finishing.

We look forward to meeting you in person to learn more about your needs and see how Linde can help you.

07 November, 2018Discover our ADDvance® range of gases and technologies for the Additive Manufacturing industry. Where we will reveal gas-enabled excellence from powder to precision parts. Find us in Hall 3 Booth D90 from the 13 – 16 November, Frankfurt Germany.

07 November, 2018Discover our ADDvance® range of gases and technologies for the Additive Manufacturing industry. Where we will reveal gas-enabled excellence from powder to precision parts. Find us in Hall 3 Booth D90 from the 13 – 16 November, Frankfurt Germany.