27 September, 2021

27 September, 2021Izadi Mecanizados, a business that focuses on high specialisation machining in power transmission solutions and gearboxes, has commenced a 2021-2025 strategic plan, planning to double its turnover figure by means of the diversification undertaken in the last two years through the acquisition of the company Denatek and the development of innovative advanced manufacturing solutions. Its R&D-centred growth commitment is based on adopting the applied technologies of the company Talens, a member of the Inzu Group, focused on the industrial vision of Izadi with the purpose of responding to the challenges posed by the thermal treatments and construction of complex forms, as well as committing to creating a solution of second useful life cycles for high added-value parts.

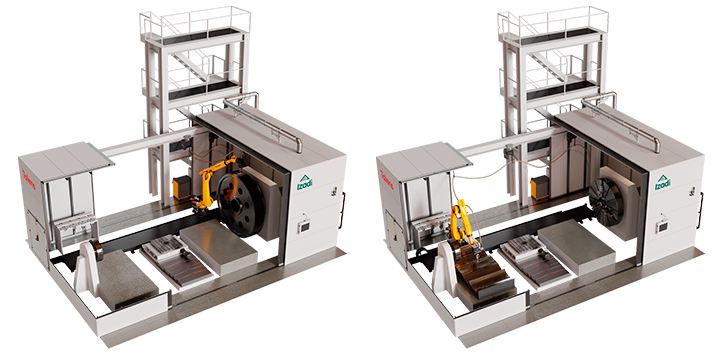

Based on this strategy, it will promote its laser business unit with the installation of a laser cell for tempering and additive manufacturing alongside Talens, with a large investment in equipment and, in R&D developments, close to one million euros in its HV-Frame programme with the support of CDTI. This is a 300 m² LMD cladding laser cell equipped with a robot for working on different types of assembly, both rotary table and outdoor work, which makes it a unique piece of equipment in Europe due to its characteristics and dimensions. The cell is equipped with tempering and cladding solutions with capacity for different types of parts both in axes, wheels and gears and in mould solutions, vanes with volumetrics of up to Ø5,000 and lengths of 8,000m between points. Thanks to the possibility of working on local sections of parts, it can considerably reduce the cost of tempering, avoiding significant deformations and improving crossed processes.

The laser business line will be strengthened with the capacities of its new subsidiary Denatek 2020, after acquiring Denatek last year with a view to diversifying its activity into engineering for CAM manufacturing and continuous 5-axes machining in high added-value components, and precision machining for sectors such as aeronautics, aerospace, the automotive industry and defence. Currently, continuing with the development of its business, the machinery and the technical office have been transferred to the new facilities built by Izadi in 2020 in Rentería, with 6,000 m² surface area and a further 4,000 m² of annexes, which will be occupied in part throughout this year and 2022.

Another area gaining ground in Izadi’s activity over the next four-year period will be its large-dimension machining business (Izadi Heavy Weight), subsequent to the absorption of Albicein and the acquisition of a tri-dimensional MCC of 5mx3mx3m, giving a second lease of useful life to high-added value parts, especially with regard to wind turbines, and also the useful life cycle and maintenance on the gearboxes line it develops alongside Aingura IIoT (InZu Group). In this case, its development is based on Industry 4.0 IIoT, using HTC systems to monitor gearboxes in real time, analysing data in order to explore, diagnose and predict anomalies in the process accurately and with minimal lag time, bringing the device closer to the data source (Edge Computing). For these purposes, a new test and power bank for transmission systems is being put in place.

In the execution of the business plan, Izadi plans to invest at least 15% of its annual turnover, amounting to 7 million euros in 2019. The expenditure will go to machinery and R&D projects, a field in which significant investment has been made in the last two years to counteract the current climate. Energy consumption is also being optimised by setting up in the coming months a rooftop photovoltaic plant with almost 700 kW, subject to future expansion.

Source: Empresa XXI.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.