18 July, 2024

18 July, 2024The Indart3D cooperative, located in Irun since 2020, is dedicated to the design, manufacture and sale of latest-generation 3D printers. As pioneers in the process of publicising a recently applied technology, Indart3D works with universities, research centres and companies in many sectors, such as the medical, textile and automotive industries. The main competitive advantage of this company from Gipuzkoa is its ability to combine modules and technologies to adapt to the specific needs of each project at an affordable cost and with optimum results.

Indart3D has been working for years with a pellet extrusion system, but mainly focused on the use of polymeric materials. However, in order to adapt to the demands of sectors with strict approval requirements, such as medicine or the automotive industry, it is necessary to advance in studies and analysis of new materials that can be used in pellet format. The aim is to increase the number of solutions that Indart3D can offer its customers, so that they can easily work with metallic or ceramic materials, among others.

The solution focuses on additive manufacturing with new materials, allowing Indart3D not only to increase its range of 3D printing solutions, but also to offer advanced capabilities such as the analysis of parts made of copper. In addition, the possibility of working with pellet and metallic or ceramic materials is confirmed, thus expanding the potential applications of its technologies.

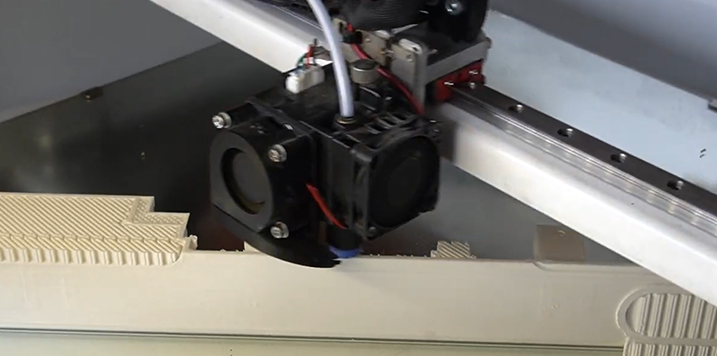

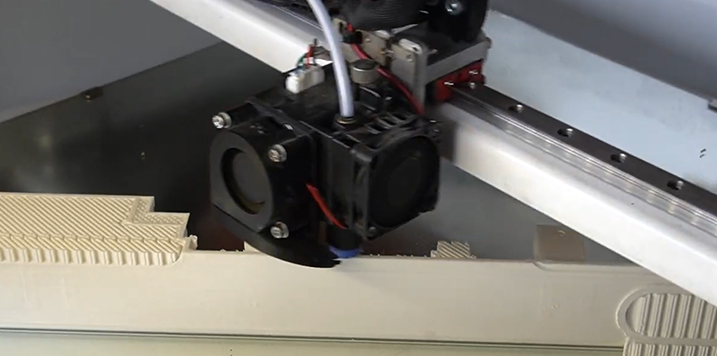

To carry out this transformation, Indart3D has incorporated several advanced technologies: the ADAM technology for 3D printing, which allows the additive printing of metals through a process of deposition of materials in layers; the Mini PRO printer with interchangeable head, which offers great versatility by being able to use different types of materials and printing techniques; and the Metal X printer for metal additive manufacturing, specialising in the creation of high-precision metal parts, ideal for industrial sectors with high quality standards.

The benefits derived from this expansion in technological capabilities are significant. Indart3D will be able to offer a wider range of customised solutions to its customers, as well as the ability to analyse and manufacture parts in copper and other advanced materials. Confirmation of the ability to work with pellets and a wider range of materials, including metals and ceramics, underlines the company's versatility. The expansion of Indart3D's capabilities in additive manufacturing with new materials underlines its commitment to innovation and quality.

18 July, 2024The Indart3D cooperative, located in Irun since 2020, is dedicated to the design, manufacture and sale of latest-generation 3D printers. As pioneers in the process of publicising a recently applied technology, Indart3D works with universities, research centres and companies in many sectors, such as the medical, textile and automotive industries. The main competitive advantage of this company from Gipuzkoa is its ability to combine modules and technologies to adapt to the specific needs of each project at an affordable cost and with optimum results.

18 July, 2024The Indart3D cooperative, located in Irun since 2020, is dedicated to the design, manufacture and sale of latest-generation 3D printers. As pioneers in the process of publicising a recently applied technology, Indart3D works with universities, research centres and companies in many sectors, such as the medical, textile and automotive industries. The main competitive advantage of this company from Gipuzkoa is its ability to combine modules and technologies to adapt to the specific needs of each project at an affordable cost and with optimum results.