24 May, 2022

24 May, 2022IDONIAL works in the circular economy applied to the field of thermoplastic materials, which can be valorised through extrusion-based 3D printing technology.

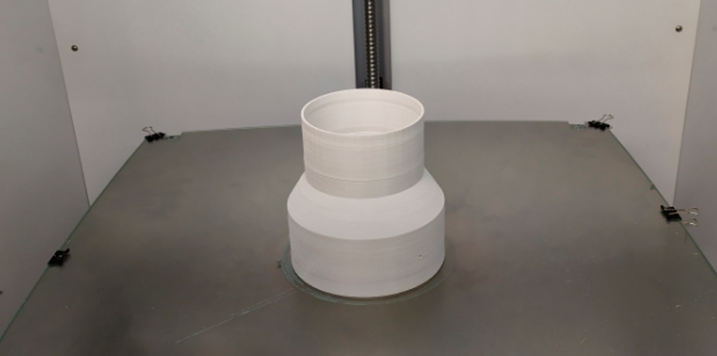

By adapting the conventional FFF process (fused filament fabrication), parts can be printed with material in the format of commercial pellets or particles of recovered material, after carrying out a suitable cleaning, preparation and shredding process.

This promotes the use of recycled plastics, derivatives or sub-products of other manufacturing materials (such as shavings and cuttings) or even parts that have already been formed but are being disposed of due to quality control rejection or end of life. All of this is applicable in a wide range of references, from technical plastics for engineering use to plastic commodities for consumer goods.

IDONIAL works to define and implement the process chain, from the preparation of the recycled starting material to the actual 3D printing parameters and operating conditions. These activities are developed within the CERVERA “READI” project coordinated by IDONIAL.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.