24 October, 2022

24 October, 2022AM Solutions (a brand of the Rösler Group) is bringing some of its extensive range of additive manufacturing (AM) post-processing technologies to this year’s Formnext exhibition on booth C81 in Hall 12 15-19 November in Frankfurt.

AM Solutions – 3D post processing technology is already respected as a dominant player in the field of post-processing of AM parts made using the full range of AM processes and in a range of materials, be they plastics, metals, or resins. The company’s success is based on the fact that it has over eight decades experience supplying finishing (or post-processing) technologies for traditional manufacturing processes, and it is able to pragmatically address the unique characteristics of AM post-processing from this perspective.

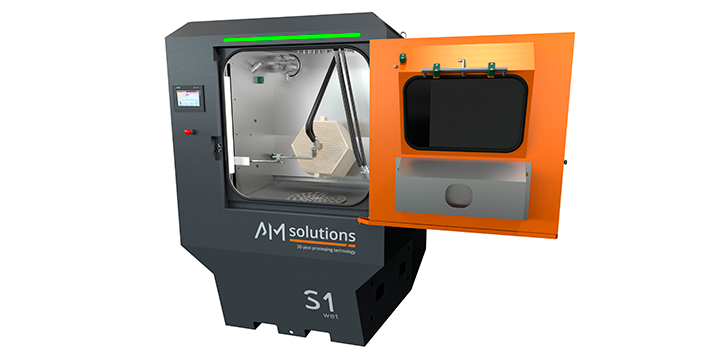

Among many other solutions, featured on the stand this year will be the S1 Wet technology, and also the S2 machine, both designed to undertake an array of specific post-processing operations.

Daniel Hund, Head of Marketing at Rösler / AM Solutions says, “What many manufacturers lose sight of when using AM is that using proven and time-worn finishing technologies (optimised to meet the specific needs of the 3D printing sector) is the best route to optimal surface finish and tolerance attainment. The goal whether using traditional manufacturing processes or AM is the same, namely to make end-use products that conform to design intent and are fit for purpose repeatably and cost-effectively. Let’s take a look at our S1 Wet technology which will be on display at Formnext, a versatile wet blast solution for cleaning and surface finishing. Wet blasting is largely neglected when looking at AM parts, but it is a clean, reliable, repeatable, and accurate process which creates parts with a consistently superior surface finish than alternative processes, and which is ideal for parts made using direct metal laser sintering (DMLS) and selective laser sintering (SLS). When it comes to powder removal on AM parts (even in hard-to-reach internal channels and features) the S1 Wet immediately washes away anything that is adhering to the work piece. In terms of surface finish, the S1 Wet promotes smoother finishes while being more precise, consistent, and repeatable. Finishes are fine and uniform, with low surface roughness being easily attainable.”

From a cosmetic surface finish perspective, the S1 Wet creates a smooth matte effect, and the less abrasive nature of process and lack of warping and bending allows for the attainment of much tighter tolerances. A key advantage is the versatility of the wet blasting process, as blast intensities and media concentrations can be easily adjusted to accommodate different materials and geometric structures to eliminate damage to part form and function. Because of this, it is advantageous for manufacturers to work with suppliers like AM Solutions — 3D post processing technology that have the knowledge and experience to advise on the numerous technical features that combine in a wet blasting process to ensure that precise and repeatable result on a wide variety of work pieces are achieved.

The S1 Wet can process metal or plastic parts individually or in batches, has a small footprint, and an integrated media cleaning and recycling system that allows the re-use of the blast media. In addition, the process water is also recycled and it can operate in manual, semi-automatic, and fully automatic operation.

Also, of enormous benefit is the fact that wet blasting is not affected by ATEX regulations as there are no dust explosion risks, a major headache when using dry blasting on materials especially titanium or aluminium. The risk of dust explosion is considerably higher for AM produced parts than for conventionally machined parts as there is always some residual printing powder left on the parts.

Also, on display at Formnext will be the S2 machine, which promotes unique parts handling and fully automated post-processing for plastic components made on the full range of polymer powder bed AM systems. Users of the S2 simply place the plastic components to be processed into the machine and the rest is automatic. A special loop belt allows single piece flow and particularly gentle work piece handling, which ensures uniform cleaning, surface homogenization — and / or peening — of the work pieces in continuous mode operation. The integrated blast media recycling system guarantees consistently good processing results. The S2 does not discolour parts because the blast media is conditioned, and the loop belt is made from polyurethane.

Hund concludes, “The S1 Wet and the S2 are just a couple of the many AM post-processing solutions that we have on display at Formnext, and we are certain that we will have a solution that is ideally suited to any show visitor’s specific application. AM Solutions has the objective of allowing the manufacture of near net shape parts with superior surface characteristics without compromising part integrity. When this is achieved, the viability of AM as a production alternative will be recognised by a growing number of companies, and the technology will be in a better position to disrupt the traditional production paradigm. AM Solutions positions itself as a company working in the AM ecosystem which has this objective as its primary focus. We would welcome the opportunity of discussing your post-processing needs at Formnext.”

A team of AM Solutions experts will be on hand to meet with Formnext attendees on booth C81 in Hall 12. The company also invites attendees requiring pre-arranged 1-2-1 meetings to email formnext@solutions-for-am.com, so specific meeting times and dates can be confirmed.

Subscribe to our newsletter. Just insert your e-mail and you will receive the latest news.