ArcelorMittal’s goal is to develop smarter steels. Steels manufactured using innovative processes that are more efficient, use less energy and emit less CO2. Cleaner, more resistant and reusable steels.

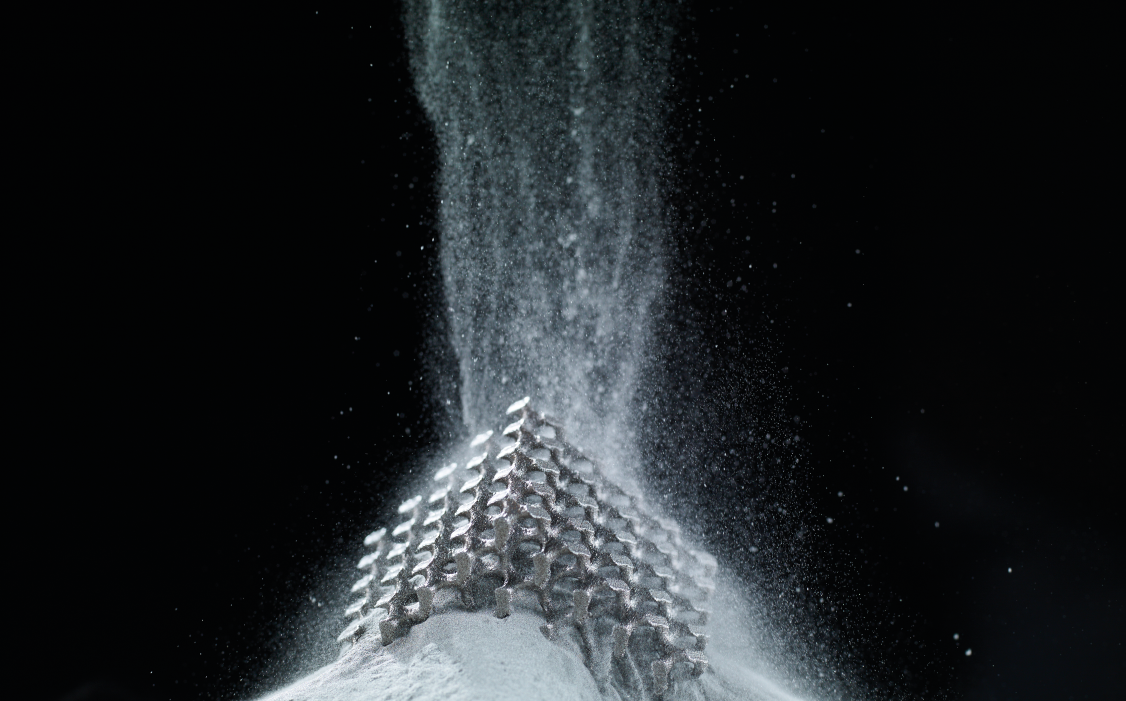

Additive Manufacturing can create new opportunities for all types of industries, enabling the production of complex, customized parts with improved properties while reducing material waste. ArcelorMittal has been producing Steel Powder in a pilot atomizer in its Additive Manufacturing laboratory in Avilés since 2018 and with more than 50 full-time researchers, it has developed deep knowledge about the interactions between steel alloy design, atomization parameters and the final properties of the printed parts.

In terms of sustainability, the AdamIQ™ range of Steel Powders has a clear commitment to reducing CO2 emissions. Its new atomizer, located in Avilés (Asturias), manufactures Steel Powder from scrap using renewable electricity and industrial gases from sustainable sources. Furthermore, the use of recycled and recyclable packaging reinforces its environmental commitment.

ARCELORMITTAL POWDERS S.L.

Calle Las Rederas, 10 - 33417 Avilés (Asturias)