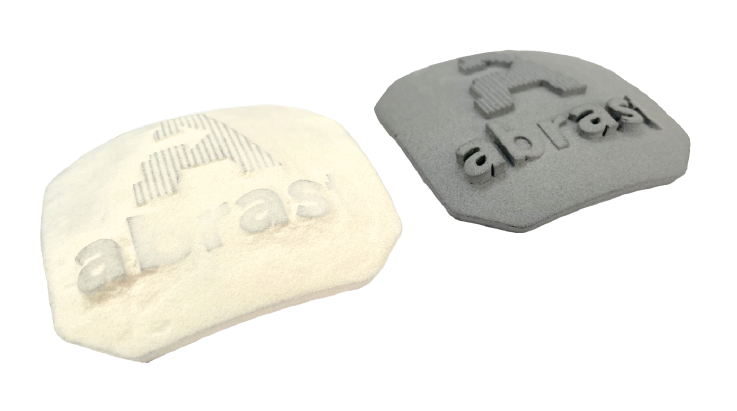

ABRAST offers a comprehensive range of mechanical postprocessing technologies for both plastic and metal additive manufactured parts. A standout among these is ABRAST MEDIA SHOT, a unique technology that combines cleaning, surface coating, and final finishing in a single step, eliminating the need for subsequent processes such as tinting. This innovative technology employs high-speed abrasive projection using a turbine, capable of treating an entire MJF or SLS print job in just 5 minutes, with benefits including high treatment capacity, color uniformity, enhanced mechanical properties, and low operational costs due to a fully automated process.

Other postprocessing options include AIR BLASTING, also known as sandblasting, which uses compressed air for abrasive projection to clean and prepare surfaces, and TUMBLING, also known as vibratory polishing, allowing for the polishing and smoothing of surfaces, minimizing roughness. Both technologies offer solutions for productions of various sizes, from small and medium to large, providing uniform and tactilely pleasing finishes.

ABRAST

C/ La Forja, nave 2, Palau-Solità i Plegamans - 08184 Barcelona (Barcelona)